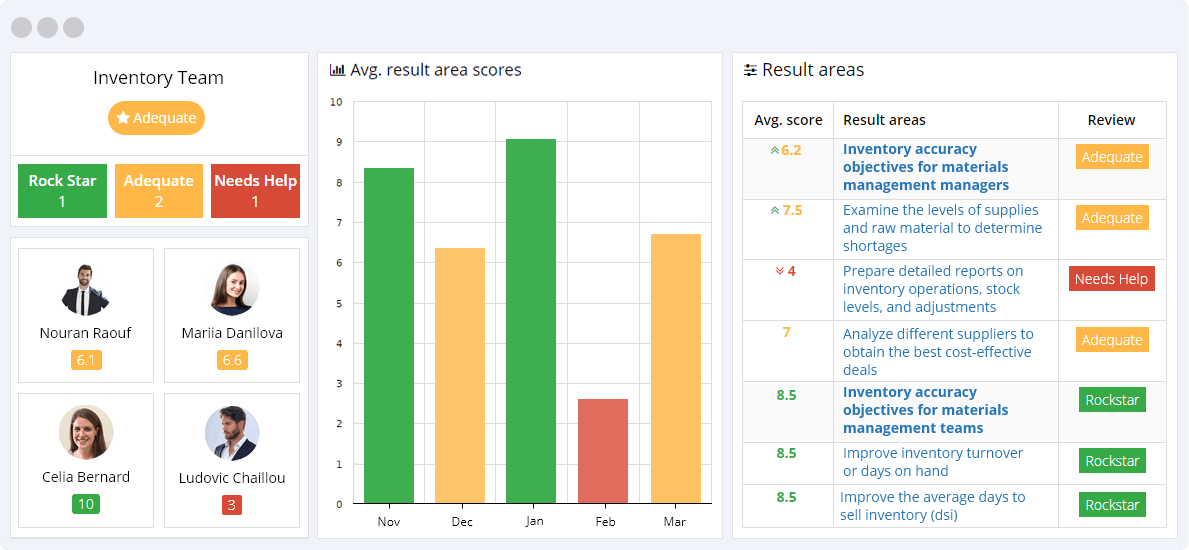

Inventory KPIs

Inventory accuracy KPIs are designed to monitor and measure the effectiveness of inventory management practices. These metrics track the materials management team’s ability to maintain accurate inventory records, optimize inventory levels, and reduce inventory discrepancies. Successful management of inventory accuracy can result in improved production efficiency, reduced costs, and increased customer satisfaction due to on-time delivery. Measuring and monitoring inventory accuracy can also help identify potential issues, such as stock outs or overstocking, before they become a significant problem, allowing for timely corrective action. Thus, inventory accuracy KPIs play a vital role in ensuring the smooth operation of a manufacturing organization.