Process Engineer Job Responsibilities

Process engineer job responsibility KPIs are designed to track and measure how well the process engineer meets their specific job responsibilities, such as developing and improving industrial processes, analyzing data, and implementing process improvements.

- Assist the quality assurance organization in establishing proper quality metrics, required measurement tools, and the necessary control plans (statistical process control).

- Document all aspects of the production process, drafting work instructions, print plans, and other required ISO documentation.

View all

- Function as the technical/engineering representative on the customer-facing teams.

- Manage trials, prototyping, and initial manufacturing runs for new products, working closely with production operators and floor management.

- Perform other duties as assigned by the supervisor.

- Prepare reports on material, product, or equipment performance for internal and external customers.

- Support the transfer of new materials or processes from technology partners into a production environment.

- Within a gated product development process, lead fully specified new product activities from product development to launch.

- Work with external customers and business management to define product requirements, and further refine those requirements into specifications over the course of the development process.

View less

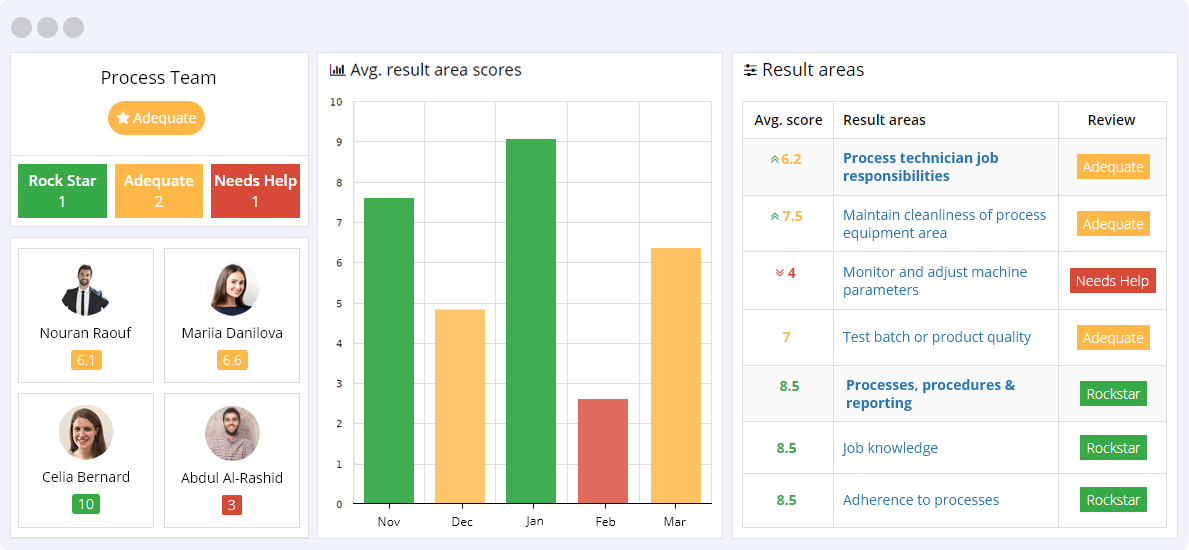

Processes, Procedures & Reporting

Processes, procedures, and reporting KPIs for process engineers and technicians are designed to monitor and improve the efficiency of industrial processes, ensure compliance with regulations and standards, and facilitate accurate reporting and documentation.

- Job Knowledge – Does the staff understand their job well. Is he/she driving his/her role effectively?

- Process Documentation – How well does the staff have the Processes and Procedures for their Job/unit documented?

View all

- Processes & Procedures – How well does the staff understand and follow the laid down policies, processes, and procedures

- Reporting – How well does the staff get their reports submitted – Timesheets, project reports, etc

View less

Process Associate Job Responsibilities

Process associate job responsibility KPIs are designed to track and measure how effectively process associates fulfill their roles, such as monitoring and controlling industrial processes, performing quality checks, and ensuring compliance with safety regulations.

- Collect Feedback from Production Employees – Maintain a good relationship with all employees involved in the production process.

- Collect Production Data and Enter into Database – To be experts in the manufacturing processes that they are assigned to improve.

View all

- Consider New Production Trends and Technology – Ability to constantly network and do research to stay on top of production trends and technology relevant to their industry.

- Identify Weaknesses in the Production Process – Create a routine for analyzing the effectiveness of the production process.

- Present Production Improvements to Management – Need good presentation and communication skills to present their ideas to the production manager.

View less

Process Technician Job Responsibilities

Process technician job responsibility KPIs are designed to track and measure how effectively process technicians carry out their specific duties, such as monitoring and maintaining industrial equipment, troubleshooting issues, and ensuring that production processes are running smoothly.

- Escalate Equipment Malfunction to Supervisor – When Process Technicians notice a malfunction with a piece of equipment, they are responsible for escalating this situation to a supervisor. This involves giving a detailed report to the supervisor so that he/she has plenty of information to come up with a solution.

- Maintain Cleanliness of Process Equipment Area – Keeping all equipment, as well as the areas in which they operate, clean. Process Technicians that work in bio-manufacturing typically have to sterilize their workplace. Working in a sterile environment requires one to religiously follow standard operating procedures, as contamination of said environment can ruin an entire batch of chemicals.

View all

- Monitor and Adjust Machine Parameters – Understanding of the equipment they are responsible for. The equipment is digitally controlled, so Process Technicians must know the right settings for each piece of equipment.

- Test Batch or Product Quality – Testing the quality of each batch of products that are manufactured effectively.

View less

KPIs or Key Performance Indicators, including real-time tracking for the industrial process department, are designed to measure an organization’s ability to design, implement, optimize, and maintain industrial processes.

Within the process department, the key performance areas that must be measured are the efficient management of the manufacturing operation’s end-to-end process control. Metrics that should be evaluated include the management of the machinery and equipment failure processes, the correct installation and setting up of machinery, quality management of manufactured products, the design and implementation of new product development plans, and the ability to interface with equipment and raw materials suppliers.