General

General supply chain KPIs include metrics such as inventory turnover, order cycle time, order accuracy, delivery performance, and supplier lead time. These KPIs help measure the efficiency and effectiveness of the overall supply chain process.

- Supplier Use – We endeavor to improve supplier use by optimizing the number of dealers used to deliver raw materials efficiently.

- Percentage of Raw Materials – We endeavor to increase the percentage of raw materials sourced from reliable and high-quality dealers to enhance factory operations.

View all

- Distance from Suppliers – We endeavor to reduce the average distance from suppliers by partnering with dealers closer to manufacturing sites to minimize transportation costs and time.

View less

Vendor Identification & Management

Vendor Identification & Management KPIs include tracking and measuring vendor performance, evaluating vendor compliance with contracts, and monitoring vendor quality and safety standards. These KPIs help to ensure that the organization maintains high standards in its relationships with vendors.

- New Vendor Setup Cycle Time – We endeavor to reduce the new vendor setup cycle time to expedite the authorization and onboarding of dealers into the vendor management system.

- Percentage of Sole-Source Vendors – We endeavor to reduce the percentage of sole-source vendors by diversifying supplier options to minimize dependency risks.

View all

- Cost of Sole-Sourced Material- Expense paid for single-sourced raw materials – We endeavor to reduce the cost of sole-sourced materials by negotiating better terms and identifying alternative suppliers.

- Percentage of On-Time Deliveries – We endeavor to improve the percentage of on-time deliveries to ensure timely receipt of materials and maintain production schedules.

- Vendor Certification Requirements – We endeavor to improve vendor certification requirements by refining and aligning them with industry standards to enhance vendor quality.

- Time Required to Certify Vendor – We endeavor to reduce the time required to certify vendors to accelerate the accreditation process without compromising quality.

- Vendor Certification Responsibility – We endeavor to improve vendor certification responsibility by ensuring effective oversight and accountability at the executive level.

- Actual vs. Quoted Lead Time – We endeavor to reduce the gap between actual and quoted lead times by improving vendor communication and reliability.

View less

Vendor Compliance & Audit

The vendor compliance and audit team is responsible for assessing vendor performance and ensuring that vendors adhere to company and industry regulatory requirements, evaluating vendor specifications, and addressing any issues that may arise. This ensures that vendors meet or exceed quality, safety, and ethical standards.

Related: Compliance Specialist, Procurement Agent, Procurement Specialist, Procurement Compliance Specialist.

View all

- Vendor Performance Measures – We endeavor to improve vendor performance measures by employing comprehensive standards to assess the performance and service levels of dealers.

- Frequency of Evaluation – We endeavor to increase the frequency of evaluation to ensure regular and thorough assessments of raw material providers.

- Vendor Delivery Performance: Average – We endeavor to improve vendor delivery performance (average) by increasing the percentage of total deliveries that meet on-schedule and quantity requirements.

- Vendor Delivery Performance: Best Vendor – We endeavor to improve vendor delivery performance for the best vendors by maintaining high standards for on-time delivery and quality.

- Vendor Delivery Performance: Worst Vendor – We endeavor to reduce vendor delivery performance issues with the worst vendors by addressing delivery delays and quality concerns.

- Average Received Materials Test Cycle Time (Days) – We endeavor to reduce the average received materials test cycle time by expediting the inventory and quality management processes for incoming materials.

- Acceptance Rate of Inbound Materials – We endeavor to increase the acceptance rate of inbound materials by ensuring higher compliance with quality control standards.

- Non-Acceptance Rate – We endeavor to reduce the non-acceptance rate by minimizing flaws and irregularities in the supplies or raw materials received.

- Percentage of Certified Vendors – We endeavor to increase the percentage of certified vendors by accrediting more local and international dealers through the procurement team.

View less

Strategic Sourcing

The strategic sourcing team is responsible for establishing and implementing procurement policies and procedures that promote efficiency and cost savings in the organization’s purchasing activities. They are also accountable for streamlining the purchasing process to ensure that it is effective and sustainable over time.

- Indirect Spending through E-Procurement – We endeavor to increase indirect spending through e-procurement by managing a higher percentage of ancillary expenditures digitally.

- Spending Managed by Procurement Group – We endeavor to improve the percentage of spending managed by the procurement group by consolidating purchases and enhancing oversight.

View all

- Spending Data Management – We endeavor to increase spending data management by routinely collecting, organizing, and evaluating a larger share of expenditure data.

- Strategic Sourcing Application – We endeavor to increase the application of strategic sourcing principles by ensuring a higher percentage of total expenditure utilizes these practices.

- Forecast Accuracy (Mean Percentage Error) – We endeavor to reduce forecast error (mean percentage error) by enhancing the accuracy of demand projections compared to actual demand.

- Materials Availability – We endeavor to improve materials availability by reducing the percentage of orders deferred due to incomplete or missing supplies.

- Percent of Correct Orders – We endeavor to increase the percentage of correct orders submitted to suppliers by minimizing inaccuracies and errors in order submissions.

View less

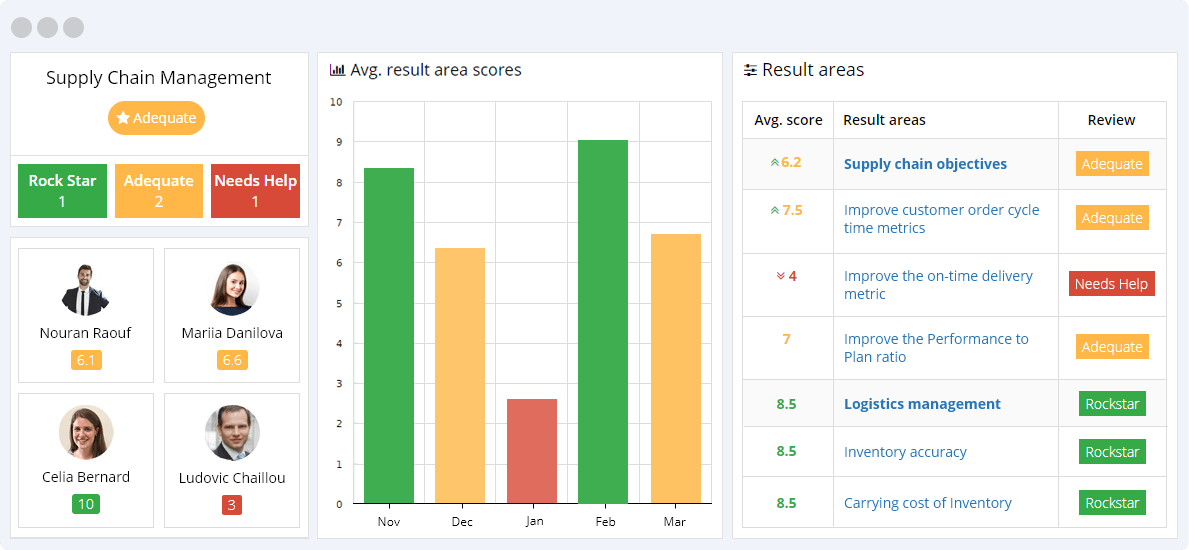

Logistics Management

The procurement logistics team works in collaboration with suppliers to ensure the timely and efficient delivery of purchased items, meeting the organization’s demands and requirements. They aim to optimize the entire procurement process from sourcing to delivery.

Related: Supply Analyst, Procurement Manager/Director, Procurement Analyst, Procurement Specialist.

View all

- Inventory Turnover – We endeavor to improve inventory turnover by accelerating the rate at which inventory is sold and transferred to customers or merchandisers.

- Average Shelf Life – We endeavor to reduce the average shelf life of items by optimizing inventory management and minimizing storage time.

- Inventory Accuracy – We endeavor to improve inventory accuracy by ensuring warehousing statistics accurately reflect in-stock inventory levels to enhance customer service and efficiency.

- Carrying Cost of Inventory – We endeavor to reduce the carrying cost of inventory by minimizing storage, labor, insurance, and delivery expenses while maintaining optimal stock levels.

View less

Procurement and Logistic Officer Job Responsibilities

Procurement and logistic officer KPIs include tracking operational efficiencies such as reducing procurement costs, ensuring timely and accurate deliveries, improving inventory management, minimizing lead times, and maintaining effective relationships with suppliers.

- Source and buy products for use and for sale in the Company.

- Monthly stock taking.

View all

- Managing the company’s store and distributing material according to usage.

- Keeping records of company stock and recording stock in and stock out. Reviewing the supply chain to ensure it is efficient and effective.

- Managing of personnel records e,g leave days, off days/sick offs, absenteeism, and late coming in accordance with the Human resource manual and filing of the same.

- Organizing and scheduling of office meetings in a timely manner.

- Receiving complaints from personnel and arbitrating where possible.

- Get updates from suppliers on price changes and availability of items.

- Provides logistical support for project activities which includes picking and delivery of client goods and purchased stock in a timely manner.

- Ensuring sound partnership with suppliers.

- Ensuring timely, efficient and effective procurement of goods, services and works, while strictly adhering to the procurement policy.

- Establishing in liaison with the relevant departments and end users, quality specifications of goods and services.

- Carrying out designated checks on quality.

- Managing disposal of obsolete and disposable items with authorization from the management team.

- Preparing reports and updating the management on any issues needing attention.

View less

Supply Chain Objectives

Supply chain management is integrated planning, implementation, and control of the flow of products, information, and money across the supply chain from the manufacturer to the end consumer. Supply chain management KPI objectives are designed to assess and monitor supply chain efficiencies, ensuring that end-to-end processes run smoothly and optimally.

- Improve customer order cycle time metrics – One of the company’s fundamental aims is to decrease the amount of time between the placement of a purchase order by a customer to the complete fulfillment of the request. This metric is tracked so that the company can gauge how well it is meeting this requirement.

- Improve disruption impact metrics – Disruption impact is the impact of a natural disaster, political event, and global pandemic on a company’s supply chain processes. Companies must design and implement a disaster management plan to mitigate the disruption of the supply chain so that the customers can still receive the goods they purchased on time.

View all

- Improve conversion rate metrics – Lead acquisition and management are some of the core business functions of a successful supply chain organization. Tracking and improving the conversion rate metrics is an essential element of the successful supply chain business so that your business keeps on moving forward and growing.

- Improve inventory days of supply metrics – The Inventory Days of Supply metric aims to ensure optimal inventory levels at all times. It measures the average time it takes for a company to move its total inventory and provides supply chain managers with the average inventory shipped per day in relation to the inventory on hand.

- Increase quality assurance time metrics – The quality assurance (QA) time metric measures how long it takes your company to complete its quality assurance life cycle. This life cycle must be as short as possible. If this life cycle is too long, it will impact negatively on customer delivery time and customer satisfaction ratings.

- Improve the On-Time Delivery metric – The On-Time Delivery (OTD) KPI measures how many deliveries the number of on-time deliveries. The more deliveries that are completed on time, the greater the customer satisfaction and productivity metrics.

- Improve the Total Delivered Cost metric – The Total Delivered Cost (TDC) metric is the total amount of money that it takes to manufacture and deliver a product. Elements such as operating costs, demand variability, inventory numbers, and supply variability must be taken into account for the calculation of this figure.

- Increase customer service metrics – The customer service KPI is an essential number to monitor and track. The higher the customer service metric, the greater the company’s profitability. High customer satisfaction ratios translate into more business for the company, resulting in increased growth and profitability.

- Improve supply variability metrics – The supply variability is the difference between the demand forecast projections and the quantity of a particular product that is shipped. Therefore, to improve the supply variability metric (or KPI), companies must increase the demand forecast projections versus the shipped product metrics.

- Improve demand variability metrics – The supply chain demand variability measures the fluctuation in customer demand. It is the projected demand versus the concrete demand and a primary inventory management KPI for the supply chain industry. In order to ensure proper inventory management, the forecast demand versus the actual demand figures must be similar.

- Improve operating costs metrics – The operating costs of a company include distribution and procurement costs, warehousing, transportation, and manufacturing costs. This KPI measurement aims to reduce the organization’s operating costs and to increase the company’s net profit.

- Improve the Performance to Plan ratio – The Performance to Plan KPI measures how well the company has adhered to its procurement, manufacturing, distribution, warehousing, and transportation schedule. In other words, this metric determines how well the organization has implemented its operational plans. This metric aims to increase the effectiveness of the Performance to Plan ratio.

- Improve inventory metrics – The Inventory metrics KPI includes “everything inventory.” This metric tracks and measures the overall inventory management, including total inventory, inventory turns, record accuracy, obsolete inventory, working inventory, non-working inventory, and item availability.

View less

Purchasing Department Objectives

Procurement KPIs, also referred to as purchasing objectives, track the efficiency of the procurement department’s business processes. They provide management with valuable insights to streamline acquisition processes, improve efficiency, and maximize ROI on all purchases.

- Increase cost savings – The cost savings KPI measures the extent to which the purchasing department can save on the cost of purchased items. The higher this metric, the more successful your procurement strategy.

- Improve cost reduction – The cost reductions KPI measures and tracks the purchasing manager’s ability to negotiate better prices on products and services. It also measures the purchasing department’s ability to improve operational efficiencies, such as reducing labor costs by streamlining and optimizing processes.

View all

- Improve cost avoidance – The cost avoidance KPI measures and tracks future savings on the purchase of products and services. The higher the cost avoidance metric, the greater the long-term cost savings.

- Reduce maverick spend – The maverick spend KPI measures the total value of all unstructured purchases that have bypassed the internal procurement processes. A high rogue spend amount costs the business a lot of money in unexpected expenses. The lower this metric, the more control the purchasing department has over its procurement processes.

- The total spend per vendor – The total spend per vendor KPI tracks and measures the number of suppliers and the spend per supplier that the procurement department depends on.

- Improve the procurement ROI – The procurement ROI measures and tracks the Return on Investment (ROI) on goods and services purchased. It is used to determine the profitability and cost-effectiveness of the procurement processes. The higher this value, the more successful the purchasing departments procurement processes are.

- Reduce the purchase order cycle time – The purchase order cycle time KPI measures the total time it takes for a purchase order to be sent to a supplier from the starting point. The lower this metric, the quicker it takes to complete the purchase order process, and the more effective and agile your organization is.

- Improve contract compliance – The contract compliance KPI measures the extent to which the purchasing department adheres to its internal processes. The closer to 100 percent compliance, the more accurate the acquisition processes are, and the greater the procurement department’s successes.

- Improve delivery time – The delivery time KPI measures how well the purchasing department functions when it comes to sourcing goods that the business organization needs, within budget, and on time. The lower this metric, the more successful the procurement department.

- Improve cycle time – The cycle time KPI measures the average time spent between the moment when the requisition from another department is submitted and the purchase order placement. In other words, this metric measures the time the purchasing department takes to fulfill the organization’s needs.

- Improve supplier lead time – The supplier lead time KPI measures the average time it takes from the supplier order placement date to the delivery date and time. The lower this metric, the more efficient the procurement department’s processes are.

- Improve the quality standards – The quality standards KPI measures the extent to which the goods purchased fit the company’s requirements. The lower this metric, the more inefficient the purchasing department’s processes. And the higher this figure, the more efficient the procurement department’s operations.

- Reduce inventory risk – The inventory risk KPI measures the risk the company takes when purchasing large amounts of inventory. Suppose the products sell too slowly or too much stock has been purchased. The company runs the risk of reaching the stock’s expiry dates: the lower this metric, the higher the purchasing department’s efficiencies.

- Increase employee learning – The employee learning KPI measures the extent to which employees are striving to improve their work quality and efficiency rates. The higher this metric, the more efficient the purchasing department’s operations and the higher the quality of work that will be delivered.

- Reduce the unit cost per product – The unit cost per product is part of the formula for calculating its sales price. This KPI measures whether the cost per unit rises above the average unit cost. If so, the product’s profit margin is decreased. The higher this KPI, the less profit the company will make.

- Using quantity as a supplier measurement – The using quantity as a supplier measurement KPI measures supplier consistency. The greater the number of incorrect items delivered than the purchase order numbers, the lower the purchasing department’s efficiencies. The lower this ratio, the more efficiently the procurement department can meet the organization’s needs for goods and services.

View less

Supply Chain Management KPIs or Key Performance Indicators are designed to measure the optimal functioning and success of the organization’s ability to manage and purchase raw materials, products, and other supplies needed for the business to function. Within this department, the critical performance areas that must be measured are the effective management of suppliers including vendor identification based on raw material cost, ability to deliver on time, and quality of raw materials, vendor compliance, and logistics management.

Continuous KPI tracking enables management to identify contradictory short-term trends to take proactive measures to rectify these tendencies before they evolve into production-stopping disasters.